Build a DIY grain mill from parts you can easily scrounge together. Save money by using your own corn grinder for chicken feed or goat feed.

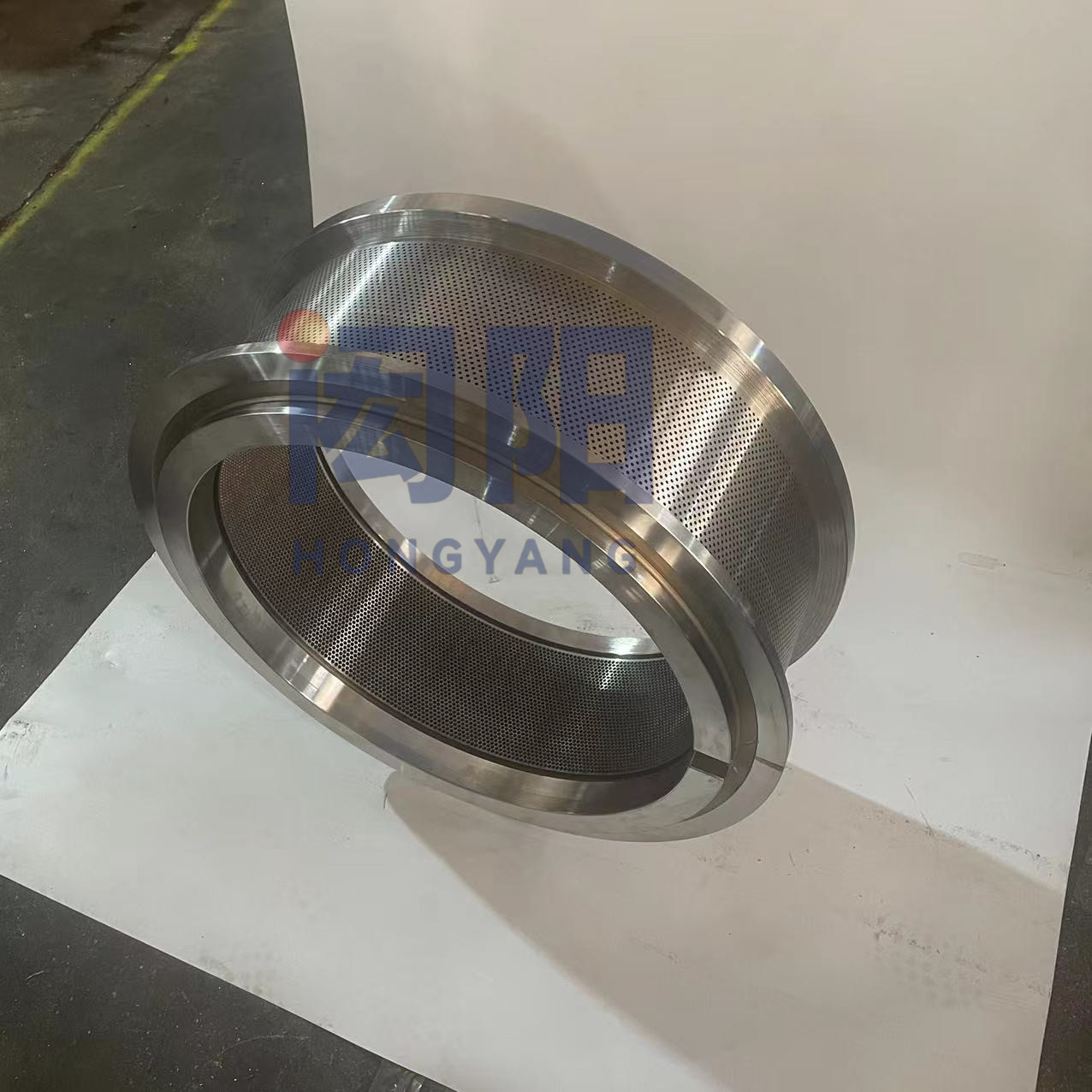

“I recently built a small roller mill that lets me grind my own organic feed fast. I use it on corn, oats, and soybeans, and unload the ground feed into 5-gallon buckets, which I feed to my goats and chickens,” says Thomas Corbin of Winfield, Pennsylvania. Vertical Ring Die

“The mill is bolted onto an angle iron frame and powered by a 1/2-horsepower electric motor, which belt-drives a pair of rollers made from the armatures off of junked car starters. The armatures measure 5-1/2 inches long by 3 inches in diameter and are mounted on pillow block bearings. A cut-out wooden board is bolted to each end of the hopper to contain the grain.

“To make the rollers, I removed the commutator bar and winding coil from each armature, keeping the shaft. Then I used a cut-off wheel with a die grinder to deepen the slots between the armature’s stack teeth so they do a better job of grinding. Once the feed has been ground, I dump it in an old cement mixer, add molasses, and mix the feed again. Then I carry it in 5-gallon buckets to my animals.

“The hopper measures 16 by 20 inches and was built by riveting pieces of sheet metal from an old washing machine. The hopper can hold almost a 5-gallon bucket of grain weighing 25 pounds, and four 5-gallon buckets are enough to feed my animals for a week.

“It takes only about 15 minutes to grind 50 pounds of feed, whereas it took an hour with my old electric-powered burr mill, which was much smaller than this one. My total cost to build the roller mill was a little more than $100.

“I’ve found that buying organic ingredients and making my own organic feed costs only about half as much as what I’d have to pay at a farm store.”

Shipping and taxes calculated at checkout.

Hammer Mill Screen Clear cart or Continue Shopping →